We fold our clothing. Our bath towels. Our sheets. And for the more artistically inspired among us, our origami. So why not our smartphones and tablets – those marvelously expansive if physically rigid windows to the world?

Turns out we’re tantalizingly close to seeing flexible OLED displays, the only barrier to foldable smartphones, a full session on flexible displays at 2018FLEX, Feb. 12-15 in Monterey, California, revealed. With prototype flexible displays in play and the basic technology available, all that’s left before adoption are efficient processing and product development.

Ross Young, founder and CEO of Display Supply Chain Consultants (DSCC) put it this way at the mid-February gathering of flexible hybrid electronics (FHE) industry players in Monterey, California: “If panel manufacturers can produce foldable OLEDs at sufficient yields to bring down costs and prices, and brands can develop products that unleash the form factor advantages of OLEDs and better communicate the performance and power benefits of OLEDs, the whole OLED supply chain will benefit.”

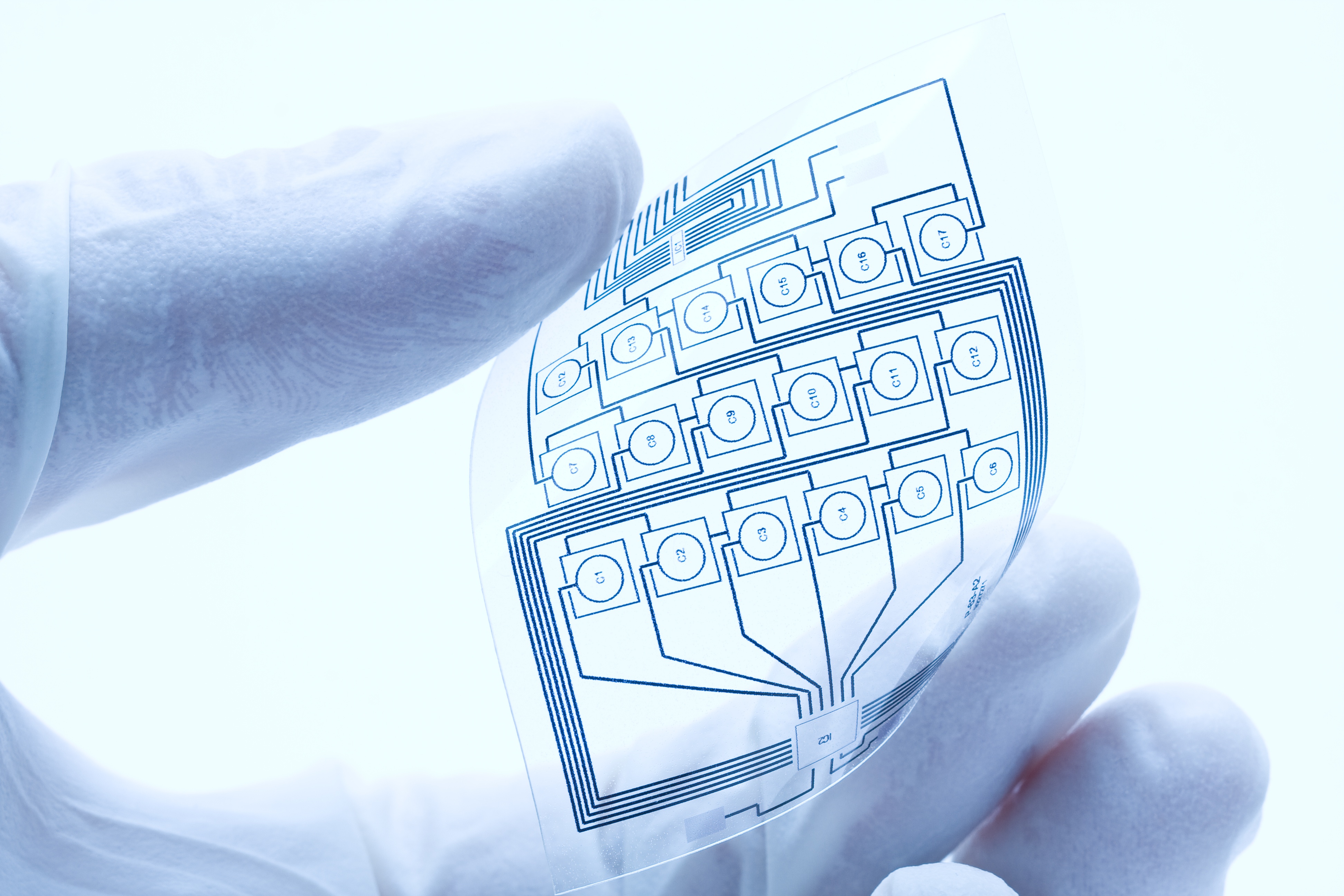

Of course, prototype development is a key step in proving out designs of OLED displays and other FHE products. Now developers now have help with a process design kit from Hewlett Packard and NextFlex’s open-source Arduino kit for rapid prototype creation and testing, formally unveiled at 2018FLEX, the 17th annual event organized by SEMI-FlexTech, the Nano-Bio Manufacturing Consortium (NBMC) and NextFlex. The conference, which co-located with the 16th annual MEMS & Sensors Technical Congress (MSTC), promotes FHE as one way to enable healthier, safer, simpler and smarter electronics products.

Typical of a fledgling industry, a slew of flexible display innovators are working to identify viable markets as they develop prototypes. But some designs have vaulted to product development as they edge closer to commercialization or have already hit the market. The list includes FHE printed antennas, smart tags for asset monitoring, a host of consumer health monitors with wireless communication capabilities, and thrilling large-area display installations like E Ink’s Dazzle® -- wrapped around one side of a new car rental center at San Diego International Airport.

Indeed, sensors for wireless medical applications drew some of the strongest interest at the event. Applications included deep brain stimulation to treat conditions including Parkinson’s, epilepsy, OCD and chronic pain (Cortera Neurotechnologies); human hydration monitoring (GE Research); patch-based wearable monitoring to enable better patient outcomes (Graftworx), and measuring blood oxygen levels using oximeters (University of California Berkeley).

In the area of manufacturing – long a focus of FLEX – low-cost, low step-count roll-to-roll processes are advancing rapidly as industrial applications adopt these capabilities. At the same time, NextFlex continues to lead the charge in improving FHE manufacturability by providing public/private funds and leading collaboration initiatives. Manufacturing has been at the heart of many FlexTech technical projects and led to FlexTech’s formation of NextFlex, America’s Manufacturing Innovation Institute for flexible hybrid electronics.

Paul Gagnon, IHS Markit, keynotes on the progress of flexible displays

Paul Gagnon, IHS Markit, keynotes on the progress of flexible displays“2018FLEX splendidly met its objectives,” said conference chair, Bob Praino, CEO of Chasm Technology. “With the keynotes, we explored the breadth of applications enabled by FHE. With the sessions, we dove into the depths of materials, processing, and components demanded by the end-applications. And the exhibit provided the hands-on opportunity to explore new industry collaborations. FHE has clearly moved beyond conceptual and, best of all, many participants found answers to product needs here at the conference.”

Beyond technology, the future brainpower for FHE was also on prominent display at 2018FLEX with college students participating in the Student Poster Session, judged by industry experts. The top three entries:

- First place: Jonathan Ting from UC Berkeley with a poster titled “Fully Screen-Printed NiO thermistor Arrays”

- Second place: Talha Agcayazi from North Carolina State University with a poster titled “Multi-Modal Array Sensing with Textiles”

- Third place: Levent E. Aygun from Princeton University with a poster titled “Sound Identification Using Physically-Expansive Sensing System”